Food and beverage manufacturers rely on controlled environments, clean utilities, and properly qualified equipment to protect product quality, extend shelf life, and support regulatory compliance. Whether used for aseptic packaging, allergen-controlled production, fermentation research, or laboratory-scale R&D, these spaces and systems must demonstrate consistent environmental performance.

For more than 50 years, Technical Safety Services (TSS) has provided environmental testing, cleanroom certification, and cGMP-aligned equipment and facility validation services that help food and beverage organizations maintain safe, compliant, and well-documented operations. Our ISO 9001-certified quality system and robust 21 CFR Part 11–compliant reporting system ensures your controlled environments, HVAC systems, monitoring platforms, and critical equipment perform reliably and withstand audit scrutiny.

Cleanroom & Controlled Environment Certification

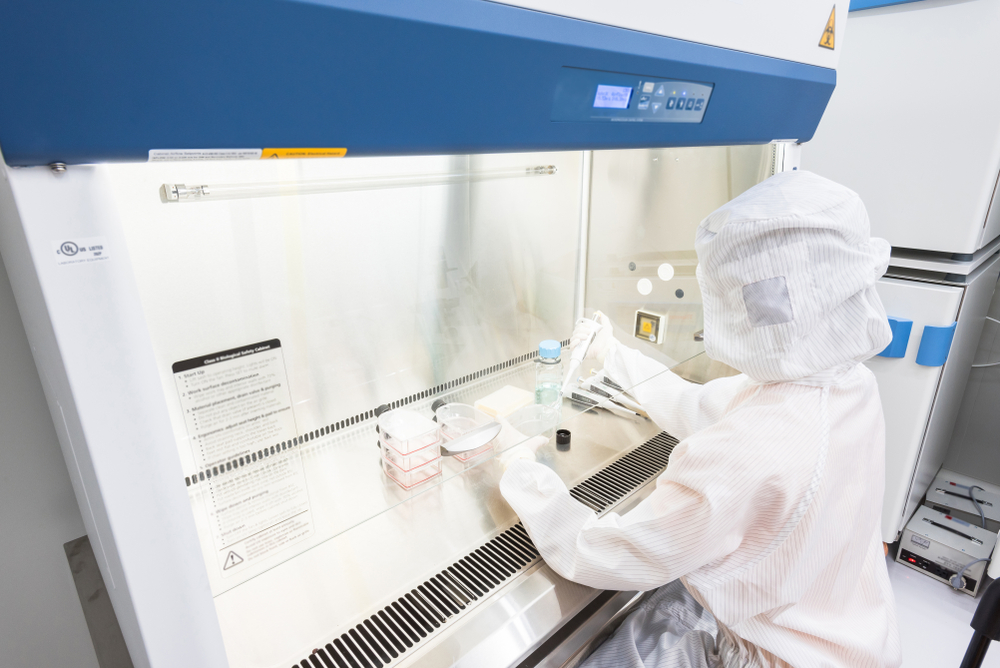

Controlled environments in the food and beverage sector may include cleanrooms, hygienic production suites, R&D laboratories, microbiology spaces, and specialized transfer or weighing areas. TSS certifies these environments to ensure they meet defined performance criteria for hygiene, airflow, and environmental control.

Routine certification services include:

- Airflow volume and velocity testing

- Room air exchange rate calculations

- Differential pressurization verification

- HEPA filter integrity testing

- Nonviable particle counting

- Viable air and surface environmental monitoring

- Temperature and humidity measurements

Expanded cleanroom services include:

- Airflow visualization (smoke studies)

- Room recovery testing

- Compressed air and gas purity testing

- Lighting, sound, and vibration measurements

These services help ensure controlled environments maintain their required state of control for safe food handling, research, or packaging operations.

Facility & Equipment Qualification (IQ/OQ/PQ)

TSS provides cGMP-aligned qualification services for controlled environments and critical equipment commonly used in food and beverage R&D, pilot facilities, and quality control laboratories. These services verify that systems are installed correctly, operate as intended, and consistently perform according to documented specifications.

TSS qualification services include:

- Cleanroom & HVAC Qualification: Verification of room classification, airflow and pressurization performance, environmental stability, and system readiness for operation.

- Building Monitoring & Automation System Qualification: Ensures environmental monitoring systems (EMS/BMS) are properly configured, calibrated, and capable of generating accurate, audit-ready data.

- Biosafety Cabinet Qualification: For food microbiology labs and R&D facilities, utilizing ISO 5 primary engineering controls.

- Thermal Qualification of Storage & Environmental Chambers: Including incubators, refrigerators, freezers, cold rooms, and stability chambers critical for ingredient storage, R&D samples, and shelf-life studies.

- Autoclave Sterilization Qualification: Cycle verification and thermal distribution studies confirm sterility assurance for laboratory and R&D applications.

- Documentation Support

- IQ/OQ/PQ protocol development

- Validation summary reports

- SOP review or development

- Requalification at defined intervals

These services are aligned with cGMP principles and support both regulatory and internal quality requirements.

Environmental Monitoring Programs

Microbial control is vital to food safety programs and laboratory integrity. TSS offers viable and nonviable environmental monitoring services for R&D spaces, QC labs, and controlled suites.

EM support includes:

- Viable air sampling

- Surface sampling

- Trend reporting

- Alert/action level recommendations

- Investigational sampling support

Applications Across the Food & Beverage Industry

TSS provides environmental testing and qualification support for controlled spaces used in:

- Aseptic and hygienic packaging

- Allergen-controlled facilities

- Fermentation and biotechnology research

- Product development laboratories

- Stability and sensory testing environments

- Pilot-scale manufacturing suites

- Food microbiology laboratories

In these areas, cleanroom performance, environmental stability, and equipment qualification are essential to ensure data integrity and product quality.

Support for R&D and Innovation Programs

Food and beverage innovation relies heavily on controlled environments and properly qualified laboratory equipment. TSS supports R&D operations with:

- Cleanroom certification

- Equipment qualification

- Environmental chamber thermal mapping

- Environmental monitoring

- Clean compressed gas testing

These services help research teams generate reliable data and maintain controlled conditions throughout development cycles.

Decommissioning of Controlled Environments

When R&D labs, pilot suites, or controlled rooms are modified, relocated, or retired, TSS offers decommissioning support in accordance with ANSI/AIHA Z9.11 and client requirements. Services include:

- Final environmental testing

- HEPA system shutdown verification

- Documentation packages supporting safe closure and transition

Why Food & Beverage Organizations Choose TSS

- ISO 9001–certified quality system

- One of the largest teams of trained certification and validation technicians in the U.S.

- Nationwide coverage for multi-site operations

- 21 CFR Part 11–compliant digital documentation

- Decades of experience in controlled-environment performance testing

- Reliable support for audits, inspections, and quality programs

TSS partners with food and beverage manufacturers, processors, and R&D groups to keep controlled environments safe, stable, and fully documented.

Ready to Support Your Facility?

Contact Technical Safety Services today to discuss cleanroom certification, environmental monitoring, and controlled environment qualification for your food and beverage operations.