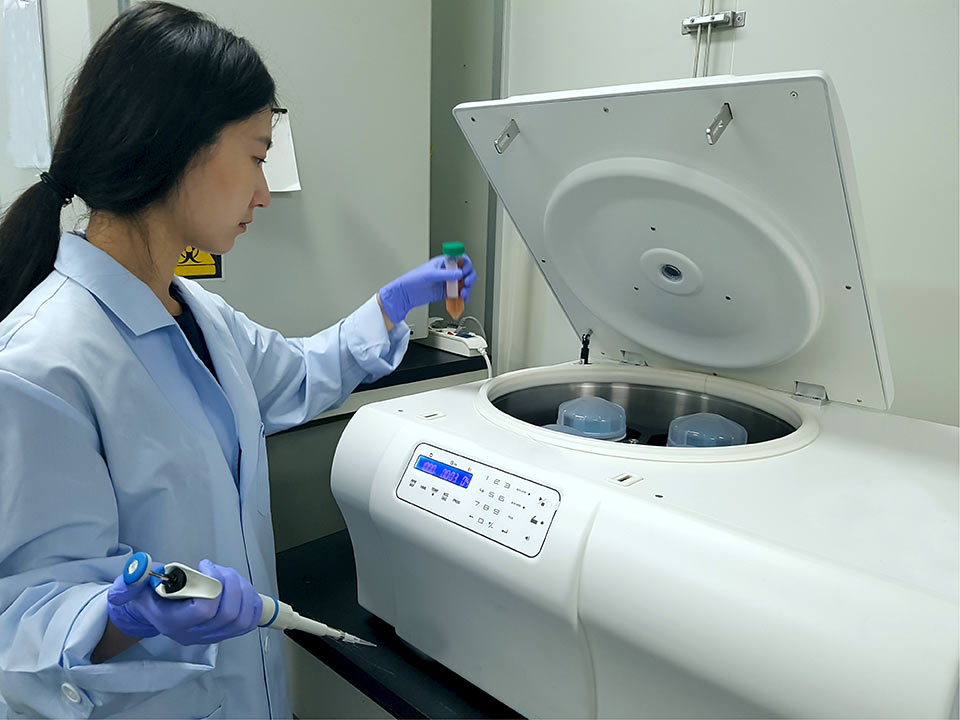

Centrifugation has continued to play an important role in laboratory separation techniques since the middle of the 20th century. Today, induction-driven motors with speeds in excess of 100,000 rpm are achieved and techniques continue to advance. TSS has calibration and maintenance services that support your research and discovery or clinical application using this critical piece of laboratory equipment.

Keeping centrifuges in proper working order is critical not only for ensuring the accuracy of lab results, but also for regulatory compliance. Governing bodies such as OSHA, NIST and the CDC have specific guidelines for the safe and effective operation of equipment including refrigerated centrifuges and other variants. Without the right expertise at your side, your laboratory may be at risk of non-compliance.

Our team of technicians, many having direct factory training, offer unmatched service and support for every category of centrifuge.

- Microcentrifuges

- Tabletops (Refrigerated and Non-refrigerated)

- Ultra-Centrifuges

NIST-traceable calibrations give you the assurance that all-affected parameters, speed, time, and temperature, are functioning within specifications and meet regulatory compliance guidelines.

Our centrifuge maintenance protocols focus on not only the equipment, but the rotors themselves, assuring you optimal performance and safety for your laboratory. Following a comprehensive centrifuge maintenance checklist, we make sure no aspect of your equipment’s operation is overlooked.

TSS "Scheduled Care" centrifuge services combine both calibration and maintenance as a one-stop service to further reduce costs. And we don't simply identify problems, we resolve them with our repair services and network of parts.

Now with 400+ technicians across the nation, your centrifuge services are in good hands.

Frequently Asked Questions

What maintenance practices do centrifuges require?

According to most manufacturers’ recommendations, centrifuges typically require routine cleaning after each use. This may include cleaning the rotors, checking components for signs of damage or wear, removing dust from vent slots, testing the speed and lubricating the rotor insert. We recommend also having the unit inspected annually by a qualified professional.

How often should a centrifuge be serviced?

Certain centrifuge maintenance tasks, such as cleaning the unit and checking for scratches and contamination, should be performed every day. Others, including detailed inspections of the components, should be done on a weekly or monthly basis. Regular preventive maintenance inspections by trained technicians should happen at least once a year. Be sure to check with your local safety officers to ensure your maintenance practices are in line with regulations where you operate.

What are some of the most common causes of centrifuge malfunctions?

Most malfunctions can be traced back to misuse, such as overloading the rotor or running the unit with the tubes out of balance. Other common mistakes include failing to secure the lid, hooking buckets so they are unable to swing freely and using tubes that are not rated for the speed.

For additional information about TSS' laboratory Centrifuge Services — and our full suite of services — please call 866-514-9514 or CONTACT the TSS regional office nearest you.