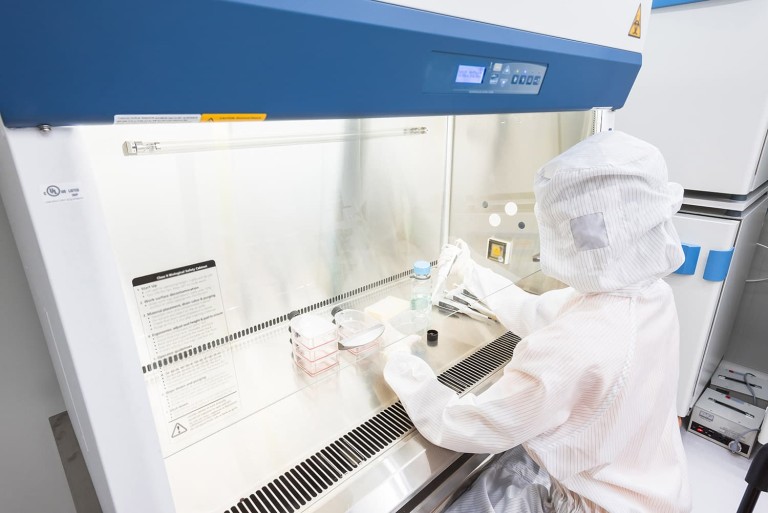

Sterility testing in lab settings helps to ensure that the proper conditions are in place for safe, accurate processes that meet industry standards and regulatory compliance requirements. These requirements and needs are particularly stringent in the pharmaceutical industry because the repercussions of unsafe or noncompliant practices can be significant and severe.

Lab sterility testing is a key component of any pharmaceutical lab production process. USP <797> outlines process requirements and recommendations for ensuring sterility in compounding drugs and includes guidelines for testing and verifying sterility as well. Here, we will explore USP <797> testing in greater depth.

Sterility Testing Methods

The following sterility testing methods can be used to ensure sterility in compounding processes. They can also be applicable to other pharmaceutical laboratory processes that require sterility and accuracy verification.

Membrane Filtration Sterility Test

Membrane filtration testing involves the physical retention of microbes from a sample using a membrane filter. The typical pore size for the filter is 0.45 µm, which allows capture of all relevant microbe types that may affect the integrity of the product. Membrane filtration enables rinsing to remove all inhibiting compounds, which is necessary to ensure an accurate reading.

Once microorganisms have been captured from the sample and inhibiting compounds removed, a culture medium is applied to the membrane filter, which remains in place for up to a 14 -day incubation period. The culture medium is selected on the basis of known or expected microbes that should be tested for. Final testing provides results based on turbidity of the sample after incubation.

Sterility Testing by Direct Inoculation

For samples that are not conducive to filtration, direct inoculation is the next suitable sterility testing method. Direct inoculation involves introducing the test sample directly into the culture medium and allowing it to incubate for up to 14 days. The sample volume must be kept to less than 10% of the total volume in combination with the culture medium.

Direct inoculation is typically carried out using one of the following culture media:

- Soybean-Casein Digest Medium (Trypticase Soy Broth, TSB)

- Fluid Thioglycollate Medium (FTM)

- Clear Thioglycollate Medium

The Sterility Testing Workflow

Regardless of the type of method used, the sterility testing workflow is generally similar, with the key requirement of removing inhibiting agents and allowing sufficient incubation time and conditions to achieve accurate and reliable test results. The workflow, in brief, is:

- Collect the sample to be tested.

- Choose the testing method based on the properties of the sample.

- Apply a means of removing inhibiting agents.

- Choose the culture medium based on the microorganisms that must be tested.

- Apply the medium or introduce the sample into the medium.

- Incubate for up to 14 days.

- Measure microbe levels through the appropriate means for the testing method and culture used.

Technical Safety Services offers microbiological laboratory services and a wide array of other services for the pharmaceutical industry. Our expertise includes facility commissioning, testing, testing design, validation, decommissioning and more. To learn more about how we can work with you to meet your requirements, contact us today.